Collaboration CONSTELLIUM / SIMAP – Grenoble INP – Univ. Grenoble Alpes

Context

The development of new high strength aluminum alloys for additive manufacturing (AM) is the purpose of major research projects worldwide, targeting applications in civil aviation, automotive and satellite industries. In this context, Constellium is developing new alloys specifically designed for Laser powder bed fusion (L-PBF). Due to the very high cooling rates characteristic of L-PBF, out-of-equilibrium microstructures with refined grains, supersaturations, and metastable phases are generated. Those microstructures are significantly different in comparison with the microstructures inherited from more traditional processing routes such as casting or forging, or with heritage alloys processed by L-PBF. It is important to take full advantage of such out-of-equilibrium microstructures to achieve unprecedented properties while avoiding some post-fabrication heat treatments. Today, the relationships between process parameters, resulting microstructures and properties remain poorly known.

Research Tasks

The aim of this PhD thesis will be to shed light on these relationships. For this purpose, we will focus on model Al-Fe-Zr alloys, designed specifically for L-PBF. Studying ternary alloys will allow to combine a fundamental understanding of the metallurgical phenomena leading to industrial issues. The research program will be divided in three work-packages:

- Effect of processing conditions on cracking sensitivity and microstructure.

- Thermal stability of microstructure in defect-free samples.

- Microstructure-property (mechanical and functional) relationships.

To do this, AM of the new designed alloys will be performed on very recent L-PBF machines offering way more freedom regarding the processing conditions (lasing strategy, melting parameters, preheating) than the ones offered by more conventional L-PBF machines. Multi-scale microstructural investigations using high-end characterization equipments will be performed (SEM-EDX-EBSD, multi-modal mapping in the TEM, 3D X-ray microtomography…) as well as advanced mechanical testing (nanoindentation mapping and digital image correlation techniques).

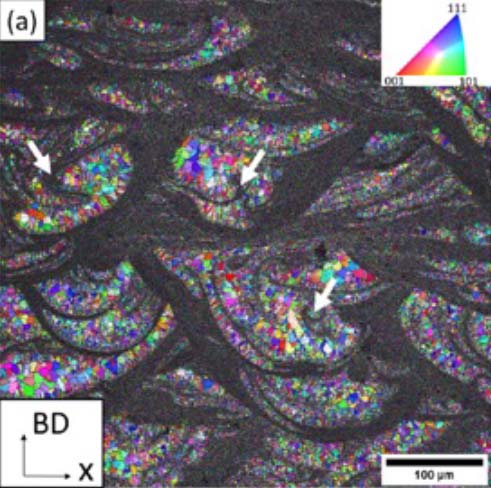

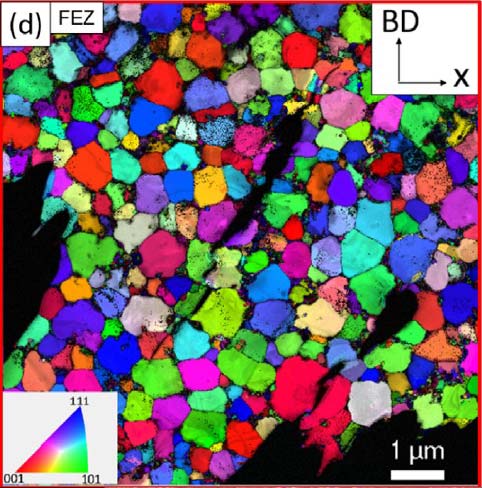

Example of microstructure of an Al-alloy produced by L-PBF:

(1) Large field of view: EBSD orientation map revealing the arrangement of several melt pools. (2) Local TEM-ACOM orientation map in a fine equiaxed zone.(From M. Buttard et al., Materialia 18 (2021) 101160)

Location

SIMaP laboratory, located on the campus of the Université Grenoble Alpes in Saint Martin d’Hères, has a long experience in the development and use of these experimental techniques and a scientific expertise in the metallurgy of aluminium alloys. There have been many join research projects between SIMaP and Constellium for many years. A common research structure has recently been created to strengthen the historical partnership between SIMaP and Constellium.

Candidate Profile & Applications

The PhD candidate will be hired by Constellium for the 3-years PhD thesis, and should have a strong background in materials science (particularly metallurgy), a taste for running experiments and the ability to carefully analyze data in an industrial context. In addition to solid scientific skills, the PhD candidate will have to demonstrate its ability to work as a team in a project involving different partners. The main part of the research will be carried out at SIMaP but frequent visits in C-TEC, the Research Center of Constellium located in Voreppe near Grenoble are planned.

UPDATE : the position has been filled